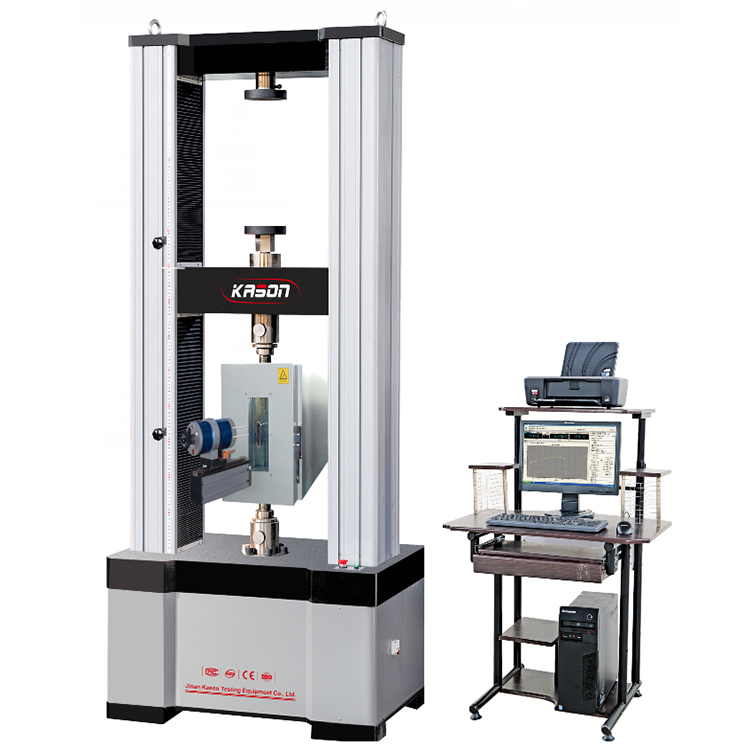

- Elektronische Universalprüfmaschine

-

Zugprüfmaschine

- Hydraulische

- Dynamisches Ermüdungsprüfsystem

-

Automatisierte Prüfsysteme für Roboter

- Serie von Stoßprüfmaschinen

- Druckprüfmaschine

- Torsionsprüfmaschine

- Biegetestmaschine

- Kriech- und Bruchprüfmaschine

-

Prüfmaschine für elastische Lager

-

Schröpfen Prüfmaschine

- Federprüfmaschine

-

Andere Prüfmaschine

- Serie von Papier- und Verpackungsprüfgeräten

- Serie von Textilprüfgeräten

- Serie optischer Prüfgeräte

- Das Spektrometer

- Prüfgeräte für Masken und Schutzabdeckungen

- Kunststoffrohre und Gummiprüfmaschine

- Andere Prüfmaschine

- Videomessmaschine

- Optischer Profilprojektor

- Koordinatenmessmaschine

- Kraftmesser

- Mechanische

- Härteprüfgerät

-

NDT Serie

-

Das

- Die metallografische

- Zubehör für

- Kammer mit hoher und niedriger Temperatur

-

Isolatorprüfmaschine

-

Reibungs- und Verschleißprüfmaschine

20KN 1000℃ Computer Control High Temperature Testing Machine

Application

This series testing machines is mainly suitable for rubber, plastic profile, plastic pipe, sheet, sheet, film, wire and cable, waterproof coil, wire and other materials in high temperature or low temperature environment, tensile, compression, bending, peeling, tearing, shear and other mechanical properties of the test; It is very convenient for users to carry out research and development, quality control work, and is an ideal testing instrument for industrial and mining enterprises, commodity inspection arbitration, scientific research units, colleges and universities, engineering quality departments.

Specifications

| Load cell | ||

| Capacity | kN | 20 |

| Calibration standard | - | 0.5 according to ISO 7500-1 - Meets ASTM E-4 |

| Accuracy grade | % | 0.5 of reading |

| Testing load accuracy | % | |

| Deformation accuracy | % | |

| Displacement accuracy | % | |

| Position resolution | μm | 0.025 |

| Force range | FS | 0.4%-100% |

| Force resolution | FS | Capacity/500, 000(fully auto scaling of single measurement range) |

| Force accuracy | % | 0.5 of reading |

| Controller | ||

| Sampling frequency | Hz | Up to 1000 |

| Closed loop control frequency | Hz | Up to 1000 |

| Software | English | |

| Load resolution | kN | Capacity/500, 000(fully auto scaling of single measurement range) |

| Speed | ||

| Testing Speed | mm/min | 0.001-1000 |

| Speed accuracy | % | ±0.5 of set speed |

| Main frame | ||

| Frame type | - | Dual test space |

| Test width | mm | 450 |

| Crosshead Travel | mm | 1100 |

| Max. Tensile Testing Space | mm | 770 |

| Max. Compression Testing Space | mm | 1000 |

| Power supply | V/Hz | 220V-50/60 |

| Overall Dimensions (L*W*H) | mm | 840 x 570 x 1850 |

| Net Weight | kG | 420 |

Furnace:

| MODEL | KS-1100G | KS-1200G | |

| Operating temperature | 300~1100℃ | 300~1200℃ | |

| Long-term operating temperature | 1000℃ | 1200℃ | |

| Heating element material | FeCrAl resistance wire | ||

| Heating body diameter | Φ1.2mm | φ1.5mm | |

| Temperature measuring element | K thermocouple (including special compensation wire) | S thermocouple (including special compensation wire) | |

| Number of heating body segments | 3 | ||

| Number of temperature measuring points | 3 | ||

| Temperature sensitivity | 0.1℃ | ||

| Temperature measurement accuracy | 0.20% | ||

| Heating zone length | 100mm | 150mm | |

| Temperature accuracy | Test temperature(℃) | temperature departure/ thermal gradient | |

| 300-600 | ±3/ 3 | ||

| 600-900 | ±3/ 3 | ||

| >900 | ±3/ 3 | ||

| Furnace inner size | Diameter* length:φ 90*300mm/ φ 90×380mm | ||

| Dimensions | Diameter* length:φ320*380mm/ φ320×460 | ||

| Tensile fixture | M12, M14, M16, M20; 1~4mm,4~8mm According to order | ||

| Operating Voltage | 3 piece of smart meter | ||

| Mains power | Limit power 5KW when heating up | ||

Hinterlassen Sie eine Nachricht

Sie können mich auch per E-Mail kontaktieren. Meine E-Mail-Adresse ist admin@hssdtest.com

Die